Power generator

Wear optimization in power generation is an extremely complex task. The challenges vary greatly from system to system. Our solutions are primarily used in biogas and wood-fired power plants.

Organic does not mean low wear

Both chemical and mechanical wear occurs in biogas plants. The specific chemical wear depends on the respective biomass medium (substrate); in some cases they react very aggressively towards all parts of the machine with which they come into contact. An effective wear protection coating should therefore protect against both acids and bases and be suitable for different substrates.

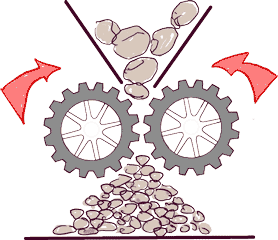

An additional challenge in biogas plants is contaminants, which can lead to a significant shortening of the service life of various wear parts in biogas production. We develop and produce wear linings as well as wear-optimized hammers and tools for all shredding machines. We also refurbish separator screws and supply highly wear-resistant screw conveyors as well as segments for subsequent refurbishment and hard facing.

Wood is awesome, but…

In many ways, the challenges of wear protection in wood-fired power plants are similar to those in other industries. At least as long as it involves storing, conveying and shredding the material. The main focus here is on mechanical wear.

The second and usually greater challenge is the waste product, ash. Ash is the most aggressive wear medium in heating plants. All components that come into contact with it are subject to heavy wear and tear and can be made durable and therefore cost-optimized using DURAPARTS. This begins in the oven and usually ends with the ash being discharged to the disposal container.

DURAPARTS offers solutions for shredding in energy production. This includes the shredding of the heating media, the conveying of the substrates upstream and downstream of the process, as well as the handling of waste products and other media. For conveying, screw conveyors, cyclones, scraper floors and fans are usually used, which are equipped with special, proven coatings. In the storage area, I specialize primarily in shovel edges and silo linings. Of course, I am also happy to take care of special inquiries about other wear-intensive components.

Solutions for energy producers

- Jaw crusher

- Hammer mills

- Cross-flow shredder

- Substrate shredder

- Scraper floors

- Screw conveyors

- Push floors

- Separator screws

- Ventilators

- Cyclones

- Drop tables

- Wheel loader buckets

- Silo linings