Steel mills

In the steel industry, downtimes are very costly and technically problematic. Therefore, wear protection and wear part optimization are of great strategic importance in this industry. Above all, unscheduled repairs shall be avoided

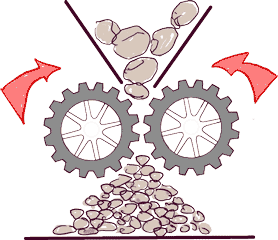

Sinter crusher – a special challenge

In particular, the systems that process sintered material are subject to high levels of wear and tear due to the extreme temperatures. In order to avoid costly maintenance work and production interruptions, the sinter crushers in particular must be protected as well as possible from wear. The standard solutions available on the market for rotors and crusher beams do not meet these requirements for several reasons and therefore have to be replaced with new components at regular intervals: On the one hand, sinter causes severe wear due to its high abrasiveness. On the other hand, the wear protection layer becomes brittle due to the high temperatures in the system and therefore cannot withstand the high impact loads for long. In addition to crusher beams and rotors, DURAPARTS also supplies ready-to-install shaft protection sleeves and discharge tables.DURAPARTS follows three approaches to meet individual needs when it comes to crusher beams and stars:

- Refurbishment of worn beams and stars using conventional methods and materials

- Use of co-developed mold systems with a significantly longer service life

- New production both conventionally hard faced and with the specially developed mold technology

Coal and coke

Steelworks often produce the coke themselves which they need to reduce iron oxide in the blast furnace. In this case, the wear parts in coke production must also be optimized beyond the scope of standard components. With special wear protection solutions, I significantly extend the service life of grinding rollers and tables, chutes, downpipes and funnels and ensure that coke production and coke storage are as uninterrupted as possible right up to use in the sintering plant.DURAPARTS delivers complete components or refurbishs them according to customer specifications.

I use established coating systems or ones that have been further developed by my partners

Wear optimization across all production steps

Conveying and storage facilities in the upstream and downstream production steps must also not be lost track on – from the delivery and storage of the raw materials, through the conveying in the production plant, the granulation of the slag through to the storage and further processing of the raw product.A particularly sensitive area is the filling of the blast furnace and its dedusting. The sieves, mixers, chutes and conveying devices, as well as the cyclones and fans that are used for dedusting, are particularly heavily stressed.

DURAPARTS offers complex lining systems, hard faced fans, crusher and roller coatings as well as conveyor tanks and screws for all of these plant areas. Our customers can be found in both the original equipment and spare parts business.

Solutions for steel mills

- Sinter crusher

- Vertical roller mill

- Suction bells

- Bucket elevators

- Dust lines

- Castors

- Protection sleeves

- Protective tubes for thermal sensors

- Seeves

- Continuous casting rolls

- Funnel

- Ventilators

- Rollers

- Tinder scrubber

- Drop tables

- Discharge chutes

- Linings