Gravel and crushed stone plants

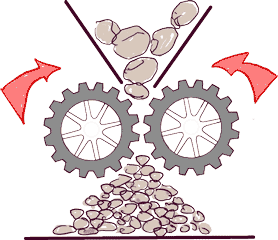

In quarries, gravel and gravel works, particularly strong impact and friction wear shortens the service life of components.

Solutions for gravel plants

From the quarry to the finished product, the extracted rock goes through many production steps: Obtained by blasting, the rock chunks are crushed using crushers and mills and sorted in sieves and classifiers. The products are classified according to grain sizes: Scrap, gravel, chippings and sand.

Crushing is carried out using impact crushers, jaw crushers or vertical mills. I offer wear-optimized solutions for all of these shredding devices, as well as for screw conveyors and blower lines, which are used to transport the bulk material obtained. In order to guarantee you wear protection across the entire production chain, we also optimize shovel edges, discharge tables and silo linings in the storage area. DURAPARTS components are used in many different companies in both dry and wet grinding processes.

The complete refurbishment of crusher rotors is carried out in my partners’ workshops, including dynamic balancing and corresponding documentation.

I work with a large network of production partners throughout Europe and am therefore able to produce optimized components as individual pieces or in small series or to refurbish existing wear parts.

DURAPARTS has made a name for itself throughout Austria as a reliable supplier of cost-optimized components, particularly in the area of inside hard faced blow pipes, elbows and branches.

Crushing is carried out using impact crushers, jaw crushers or vertical mills. I offer wear-optimized solutions for all of these shredding devices, as well as for screw conveyors and blower lines, which are used to transport the bulk material obtained. In order to guarantee you wear protection across the entire production chain, we also optimize shovel edges, discharge tables and silo linings in the storage area. DURAPARTS components are used in many different companies in both dry and wet grinding processes.

The complete refurbishment of crusher rotors is carried out in my partners’ workshops, including dynamic balancing and corresponding documentation.

I work with a large network of production partners throughout Europe and am therefore able to produce optimized components as individual pieces or in small series or to refurbish existing wear parts.

DURAPARTS has made a name for itself throughout Austria as a reliable supplier of cost-optimized components, particularly in the area of inside hard faced blow pipes, elbows and branches.

- Impact crusher

- Jaw crusher

- Vertical mills

- Seeves

- Screw conveyor

- Blow pipes

- Gravel scrubber

- Elbows

- Shaft protection sleeves

- Rotary valves

- Drop tables

- Inlet funnel

- Grabber

- Wheel loader buckets

- Silo linings